MAIN MENU

CATALOG INDEX

BY ALPHABETICAL

ORDER

For more info:

JSi@jsits.com

- [ Bench Ovens

]

- [ Economical

Forced

Convected

Ovens

]

- [ Heavy Duty

Oven ]

- [ Hybridization

Oven

Model

1012 ]

-

[ High-performance

bench-top

ovens ]

- [ Laboratory

Ovens ]

- [ NCAT

Moisture

Determination

Oven ]

-

[ Oven-logger

]

- [ Vacuum

Oven ]

- [ Vacuum

Oven / Station ]

- [ Rolling Thin

Film

Oven

]

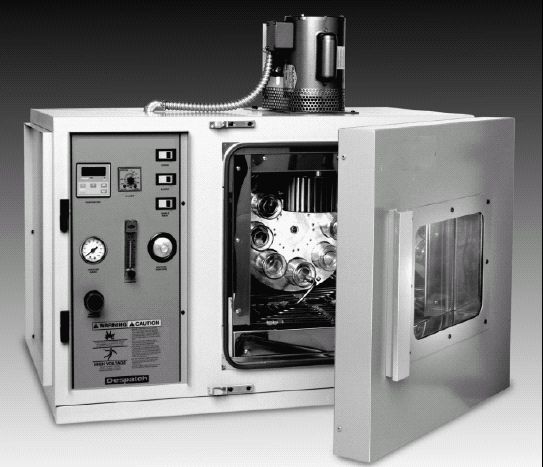

Rolling-ThinFilm-Oven(회전박막가열장치)

JSMO-31

West Virginia University

|

용도:시공단계에서의 아스팔트 노화 저항성측정 Rolling-ThinFilm-Oven (RTFO) meets requirements for Superpave thin

film and loss on heating tests. Asphalt binder is rapidly aged during the construction process.

Heating the asphalt to mixing temperature and blending it with the

aggregates causes rapid oxidation and volatilization. The Rolling

Thin Film Oven is used to condition asphalt binder samples to simulate

the change in binder characteristics during the construction. Features -Large observation window in door provides

The Rolling-ThinFilm-Oven is preferred by SHRP for simulating short

term aging of asphalt binders. 230V/( 60Hz )

|

|

|

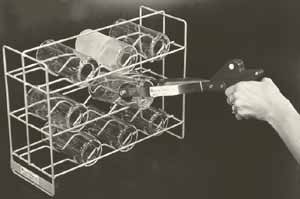

Bottle Cooling Rack Bottles Tongs |

|

|

Bottle Scraper

|

|

| CAT. NO. | DESCRIPTION |

| DERTF-0000.......7350. | Rolling-Thin Film- Oven |