CATALOG

INDEX

BY ALPHABETICAL

ORDER

For more info:

JSi@jsits.com

Specifications |

|

|

The SPECTRAmax 340PC384 provides everything you need to measure absorbance in the visible range, including temperature control, robotics-compatible interface and SOFTmax® PRO data analysis software.

|

|

The optical design of the SPECTRAmax 340PC384 truly mimics a dual-beam spectrophotometer. Each well has its own sample beam and reference detector. The eight-channel system, consisting of eight sample beams and eight reference beams, delivers both superior precision and speed of reading across the microplate.

No Interference Filters Required

The SPECTRAmax 340PC384 has a monochromator instead of interference filters. Simply select the absorbance maximum of your sample and let the monochromator tune to that exact wavelength. Or scan up to 384 wells at any time to determine the best assay conditions. The wavelength and scanning ranges are from 340-850 nm in 1 nm increments. It’s like having 511 filters built-in so you will always have the correct wavelength.

Measure Fluid Volumes in Individual Wells

The patented* PathCheck® sensor measures the depth of the liquid in each microplate well. This information can be used to normalize absorbance values to a 1 cm pathlength so they will agree with measurements made in a standard 1 cm cuvette. You can also use this feature to calculate concentrations without a standard curve and expand the dynamic range to 6+ OD. PathCheck can accurately measure liquid volumes down to 5 µL to test the accuracy and precision of liquid handling devices.

Applications

The SPECTRAmax 340PC384 can handle a wide variety of applications including:

| ELISA/EIA | |

|

Cytoproliferation/Cytotoxicity |

|

Kinetic ELISAs/Enzyme Assays |

|

ß-galactosidase Reporter Gene |

|

Colorimetric Protein |

|

NAD(P)H-based assay |

Leading Microplate Data Analysis Software

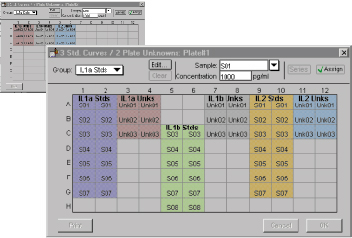

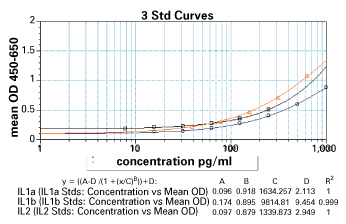

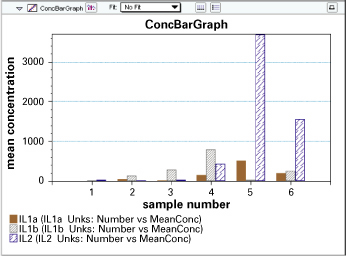

SOFTmax® PRO microplate data analysis software provides flexibility in experimental design, set-up, analysis and reporting, giving you the opportunity to customize your assays exactly as you require. You can password-protect your data, choose from nine different curve-fitting routines and use default data reduction, or set up your own formulas for analysis. You can even analyze and combine data from different plates. (See Figures 1, 2 and 3.)

|

|

Figure 1: Standards for multiple calibration curves and unknowns can be run on separate plates. |

|

|

Figure 2: Multiple calibration curves can be plotted on one graph. |

|

|

Figure 3: Results from unknowns run on different plates and different calibration curves can be plotted on one graph. |

Optical Performance Validation

The optional SPECTRAtest™ Validation Package provides an NIST-traceable solution for validating the SPECTRAmax 340PC384. The following measurements are automatically made by SOFTmax PRO: baseline noise, dark noise, optical alignment, wavelength accuracy, photometric linearity and wavelength precision.

Photometric Performance

Photometric Performance

| Wavelength Range |

340-850 nm | Photometric Range | 0 to 4.000 OD | |

| Wavelength Selection | Monochromator, tunable in 1-nm increments | Photometric Linearity (405 nm) |

0 to 3.000 OD | |

| Wavelength Bandwidth | 2 nm | Photometric Accuracy (340-850 nm) | < or = 0.006 OD ± 1.0%, 0-2 OD |

|

| Wavelength Accuracy | <± 1.0 nm | Photometric Precision | < or = 0.003 OD ± 1.0%, 0-2 OD | |

| Wavelength Repeatability | ± 0.2 nm | PathCheck Measurement Error | < 5% compared to a 1 cm cuvette | |

Microplate Read Time (single wavelength) |

||||

| Endpoint Read Time | 96 wells in 9 seconds 384 wells in 29 seconds |

Minimum Kinetic Interval | 96 wells in 9 seconds 384 wells in 29 seconds |

|

Temperature Regulation |

||||

| Temperature Range | Ambient + 4 C to 45 C | |||

*U.S. Patent Number 5,959,738 and 6,188,476

** Specifications subject to change

|

|

Top Top |

|

|